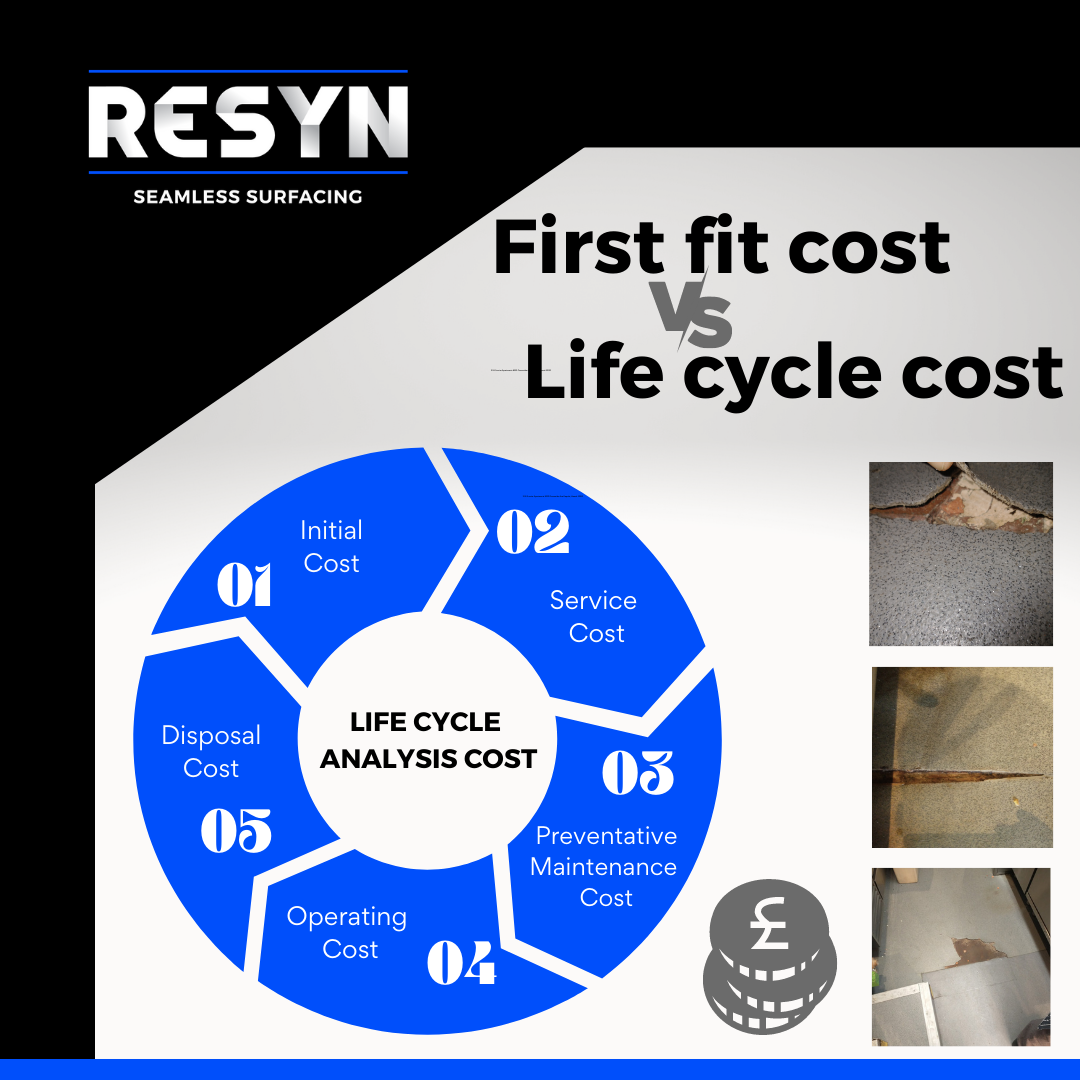

When considering a new floor finish, it is essential to consider not only the initial cost of the product but also the life cycle cost. Undertaking a life cycle resin flooring costs analysis considers the cost over a product’s lifetime, including initial cost, service cost, preventative maintenance cost, operating cost, and disposal cost.

Often budgets only consider the initial cost of a product, and whilst this may be the cheaper alternative at the time, spending less on upfront costs may not offer long-term savings. Maintenance and repair costs can mount up over the years, significantly increasing the product’s life cycle cost.

Resin flooring costs are typically more expensive to install than other floor finishes, such as vinyl or tiles, however, when considered in comparison over a life cycle, resin flooring costs may offer a cheaper and more sustainable solution.

Resin flooring has an excellent bond to most substrates, including concrete, screed, tiles and WBP Hardwood Marine Ply. This bond not only makes the floor exceptionally hardwearing, but it also dramatically reduces the risk of delamination.

Vinyl sheet often fails at welded joints and seams, and subsequently, incur repeated maintenance costs. Any damage can lead to water ingress and further failure of the floor making the need for a larger repair a necessity. Damage can also lead to an increased risk of listeria and other harmful bacteria that are associated with stagnating water.

Resin flooring is installed as a seamless solution and with no weak points, improves hygiene whilst also reducing maintenance costs.

Vinyl sheet can also become brittle over time and/or when exposed to heat, again accelerating the need for removal or repair. At the end of the product’s life cycle, vinyl must be disposed of correctly before a new floor can be installed. In many cases a resin floor can be overcoated without being removed, again improving the product’s sustainability.

The cost of undertaking maintenance can not only be limited to the cost of the product and installation, but companies also need to be mindful of the costs associated with any disruption to the business.

Many of our customers, who had previously been spending thousands of pounds through ongoing maintenance and repair, are now benefiting from hardwearing, reduced maintenance resin flooring costs. Take a look at our case studies to see examples or our YouTube channel.

For further information or to discuss a project, please contact us on 01778 343670 or take a look at our about us page.