Resin Flooring Contractors

Degafloor® MMA Resin Flooring

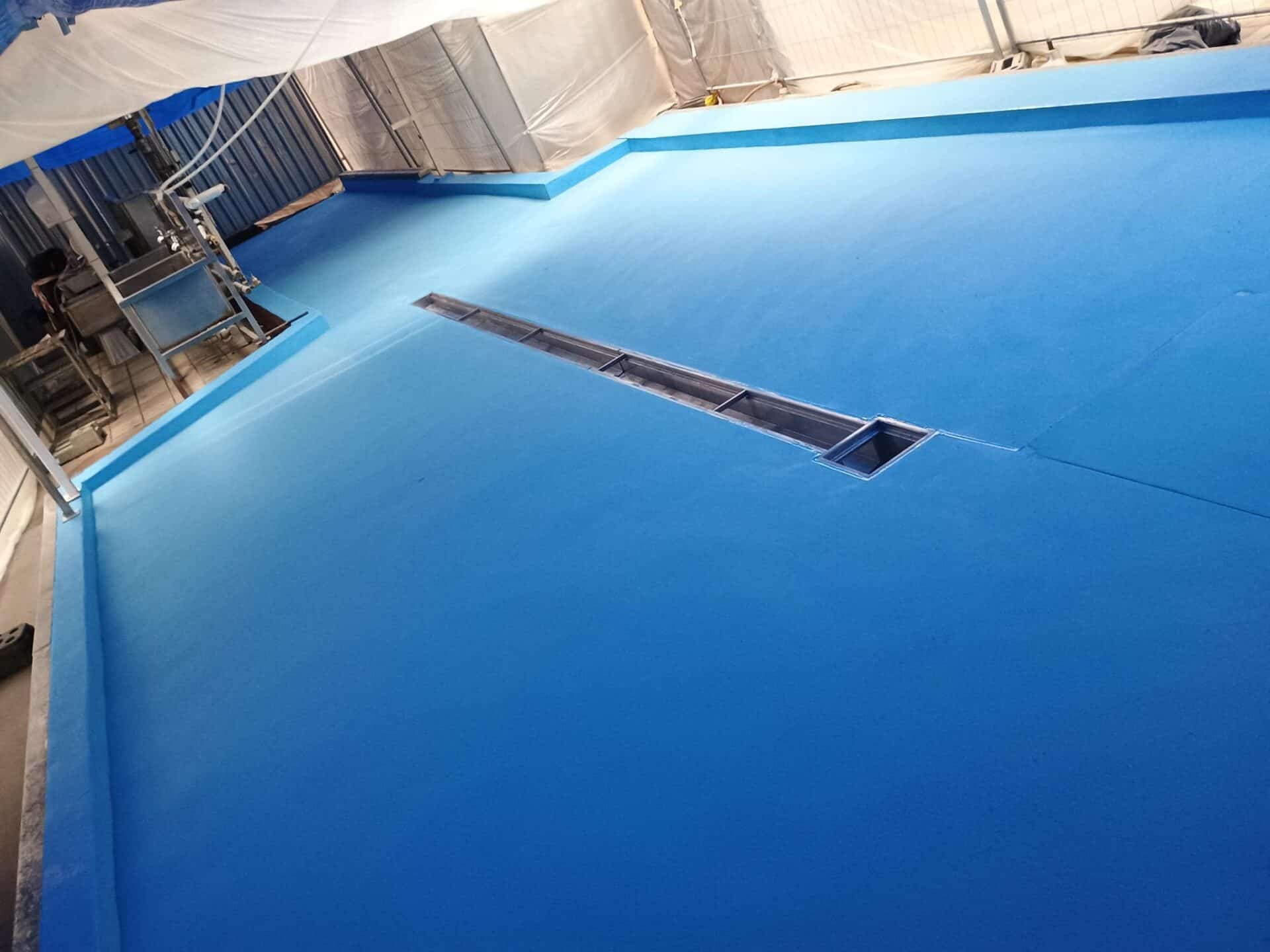

Polyurethane Resin Flooring Systems

Epoxy Resin Flooring

Floor Screeds

Floor screeding services

Concrete repair services

Car Park Surfacing

Line Marking

Installation

New Build / Redevelopment Project

Refurbishment

Turnkey Solutions

Aftercare

Other Services

Sectors

Commercial Resin Flooring

Industrial Resin Flooring

Airports

Commerical Kitchens

Schools

Manufacture and Engineering

Factories

Food and Drink

Healthcare and Hospital

Pharmacuetical

Prison Service

Leisure and Hospitality

Theme Parks

Hotels

Public Sector

Fire Service

Retail

Stadiums and Arenas